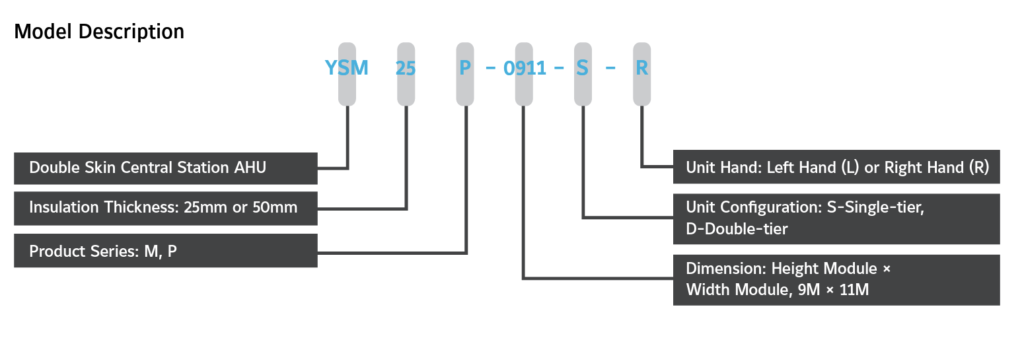

YSM Air Handling Units

The YSM series double skin air handling unit (AHU) consists of 81 models with air volumes ranging from from 1,200 ~ 99,180m3/h and standard internal static pressures as high ±1000 Pa (for 25/50mm thickness panel), to ensure maximum flexibility and the best solution for your application.

YSM air handling units are modular in design and can be manufactured in varied configurations, with a wide selection of components, to meet customer requirements. Units are suitable for shopping malls, hotels, office buildings etc. which in today’s world demand improved indoor air quality requirements, and can also adapted to the hygiene and performance requirements of sectors and industries that depend on ultra-cleanliness, such as hospitals, pharmaceuticals, electronic factory etc.

YSM has two series YSM-M and YSM-P with different casing design and casing performance to meet various customer needs.

YSM Product Features

Selection Software Overview

AECworks YSM Selection Software Features

Custom Made

- The user-friendly selection software UI makes for easy selection.

- The organized project management system quickly responds to customer’s increasing design requirements.

- The flexible parametric design improves the design efficiency and effectively shortens design time.

Powerful Function

- Diverse configurations include simple and practical single-tier unit, slim unit and double-tier unit with smaller footprint area to meet various customer requirements.

- 81 preferred standard models are available to satisfy both conventional application and special applications with high requirement for dimension flexibility.

- Providing 26 segments available as an option.

Professional Software for Coil Selection

- Providing diverse rows of coils, circuit designs and fin options, the software is available to calculate coil performance for different operating conditions and environments, and can optimize core components configuration and improve efficiency of heat exchange.

Comprehensive Output Reports

- Comprehensive performance report is provided.

- Scaled assembly drawing with automatic output is provided for professional’s direct use.

- Psychrometric I-D chart is provided to help to determine air state parameters in each functional segment and visually reflect the changes of air parameters.

SEGMENT SPECIFICATIONS

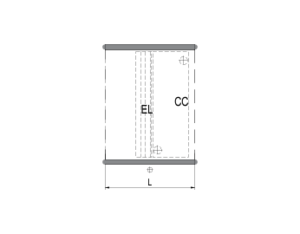

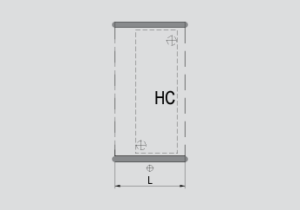

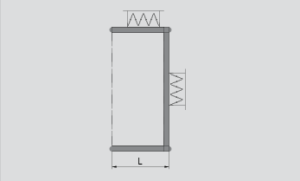

Length (Module) (for reference only)

Damper located at front: L=5MDamper located at top or side: L=Dmp_L=5M~32M(Dmp_L is length module following air flow direction at side or top damper, determined by model and damper air flow rate)

Optional

Damper arrangement, Flange, Manual damper, Motorized damper without actuator, Motorized damper with On-Off or analog signal actuator, Access door, Marine light

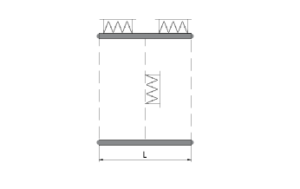

Length (Module) (for reference only)

L=Dmp_L=5M~32M(Dmp_L is max length module following air flow direction at side or top damper, will be determined by model and damper air flow rate)

Optional

Damper arrangement, Fresh air ratio, Flange, Manual damper, Motorized damper without actuator, Motorized damper with On-Off or analog signal actuator, Access door, Marine light.

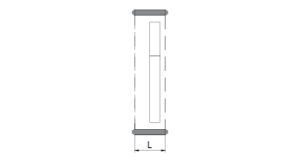

Length (Module) (for reference only)

L=EA_Dmp_L +OA_Dmp_L=10M~36M (EA_Dmp_L is length module of exhaust air damper following air flow direction, OA_Dmp_L is length module of outdoor air damper following air flow direction, and it is determined by model and damper air flow rate)

Optional

Damper arrangement, Exhaust air ratio, Flange, Manual damper, Motorized damper without actuator, Motorized damper with On-Off or analog signal actuator, Access door, Marine light

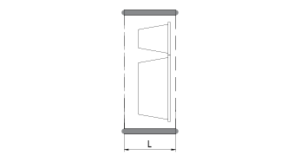

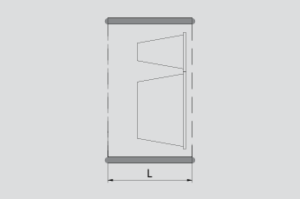

Length (Module) (for reference only)

L=4M 300mm Bag filterL=5M Plate filter+300mm Bag filterL=6M 500mm Bag filterL=7M Plate filter+500mm Bag filter

Optional

G3/G4 Plate filter; G3/G4/F5/F6/F7/F8 Bag filter,Bag filter length 300/500mm, Single bag filter,Plate and bag combination filter,Without filter (only offer bag filter frame),Spare filter, Pressure difference gauge, Access door

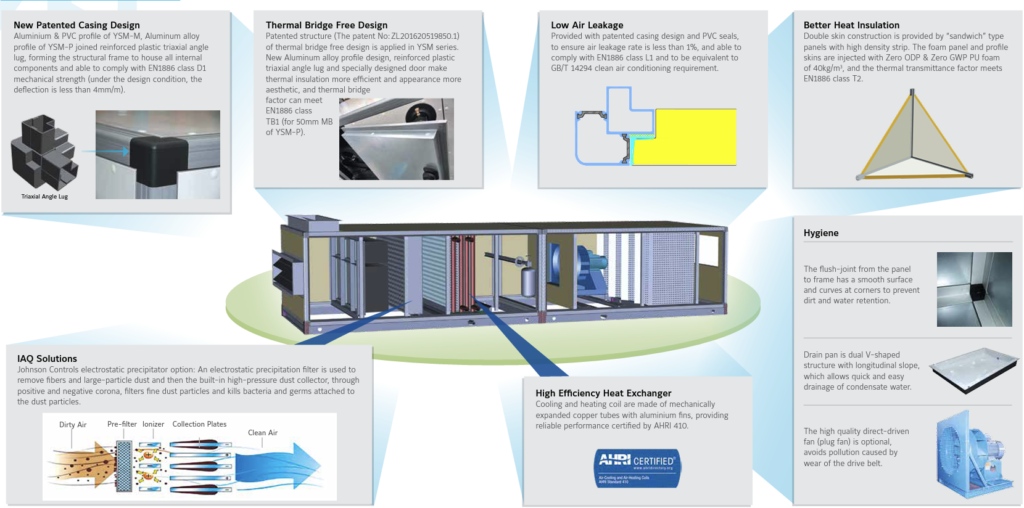

Length (Module) (for reference only)

L=5M~11M1. It is determined by coil row and combination mode2. Evaporative humidifier, droplet eliminator installed in coil segment, and does not occupy a separate segment

Optional

1~12R Cooling coil+1~4R Heating coil,1~12R Cooling coil+1~2R Steam coil, Dual cooling coil, Steel/copper header, Piping direction, Droplet eliminator, 50/100/150/200mm Evaporative humidifier (EV), Humidifier brand